Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

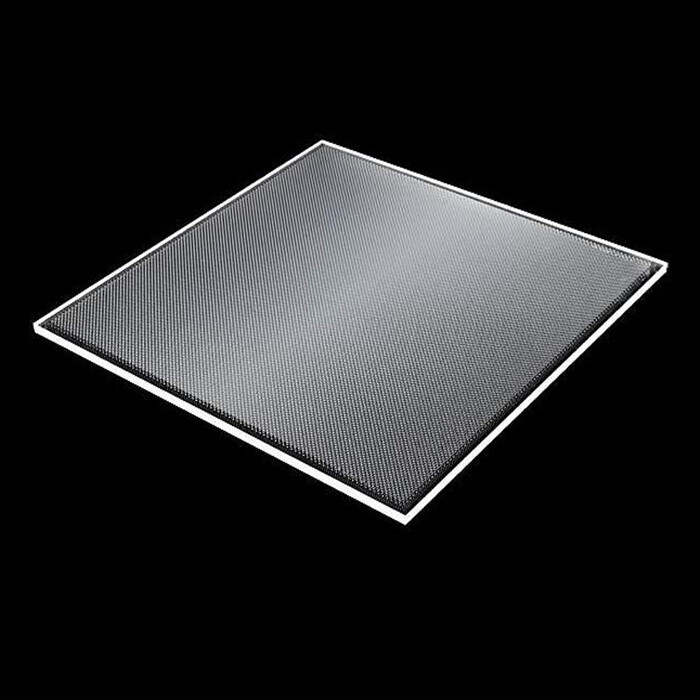

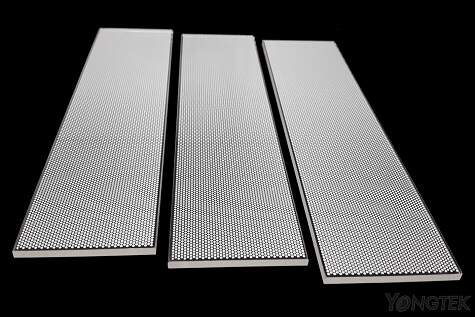

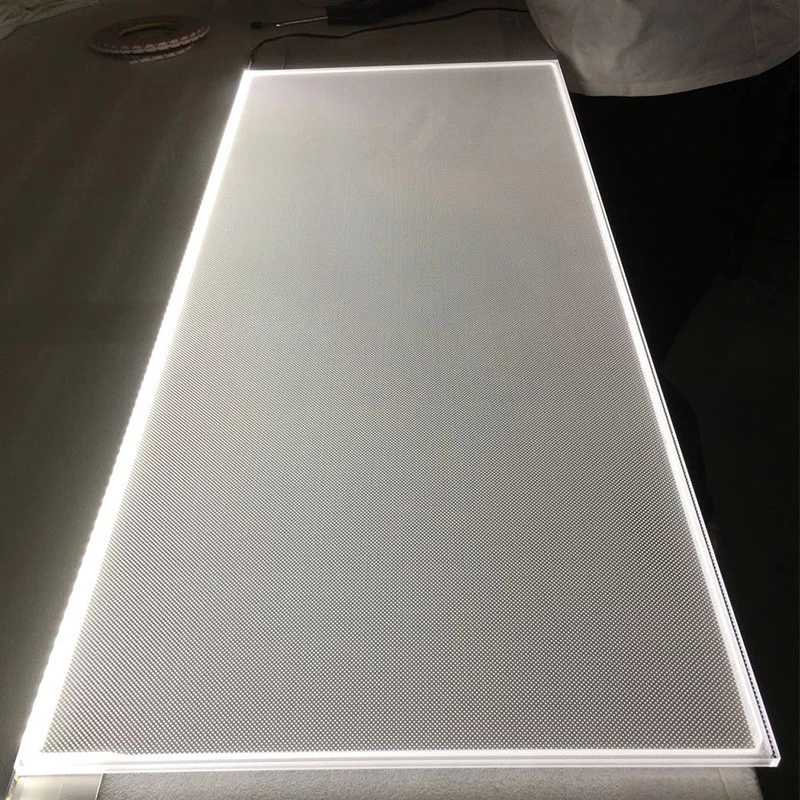

Lgp Acrylic Sheet

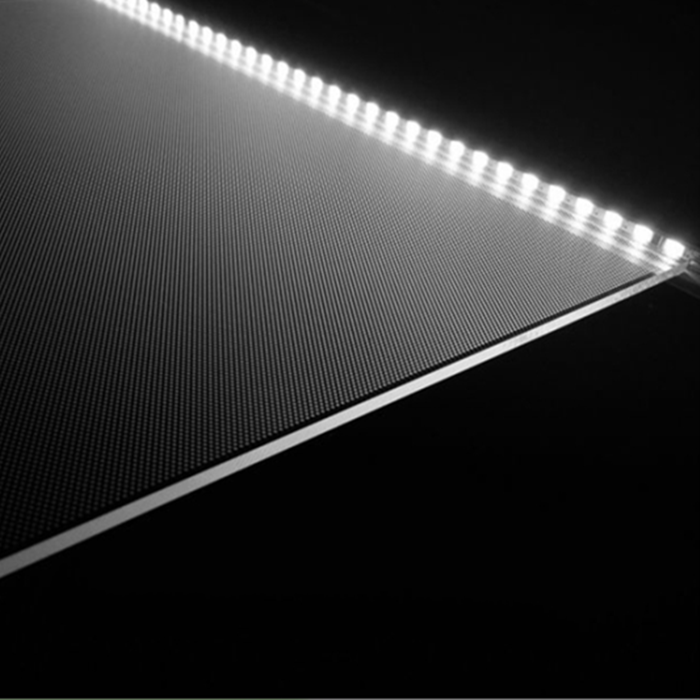

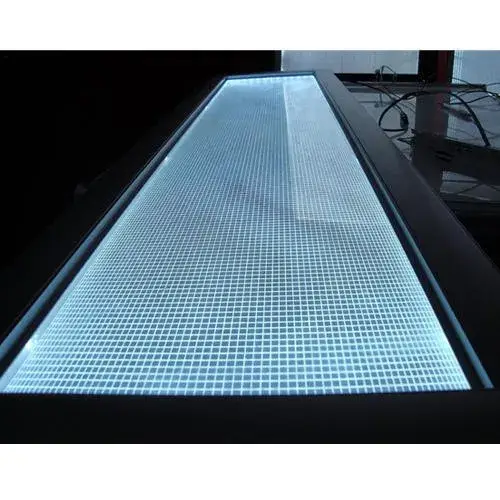

A transparent acrylic panel manufactured from virgin sheets of pure PMMA is called a Light Guide Plate (LGP) acrylic sheet. It uniformly disperses the light from the light source across the acrylic panel's entire top face. It is essential for maximizing light uniformity, creating a compact backlight, and reorienting lines or dot light sources, like LEDs or accent lamps, to the plate light source.

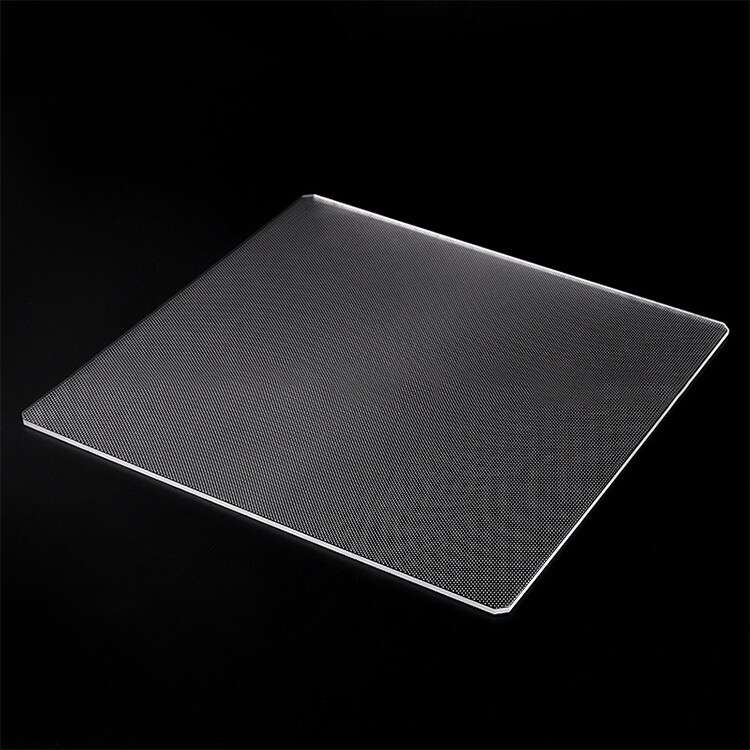

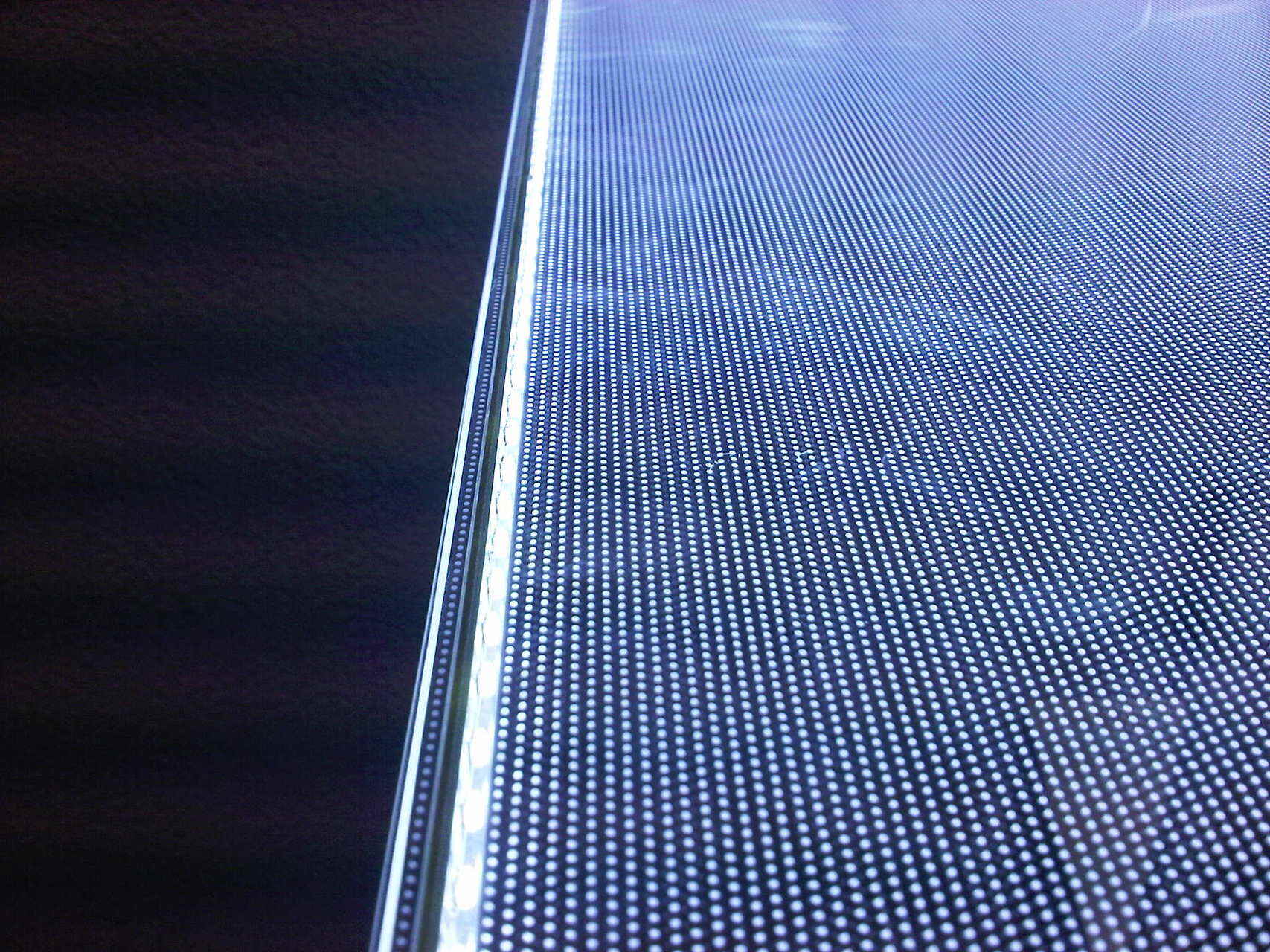

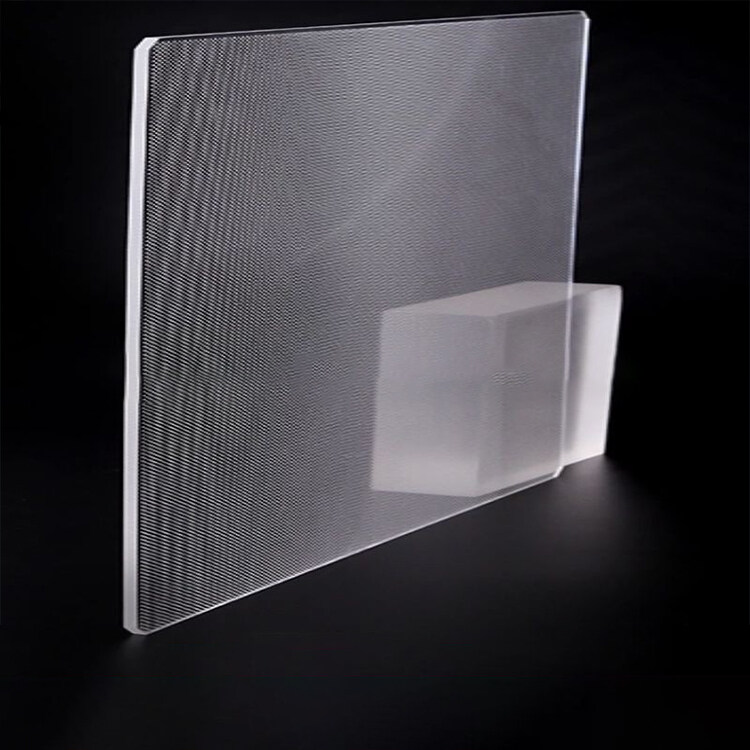

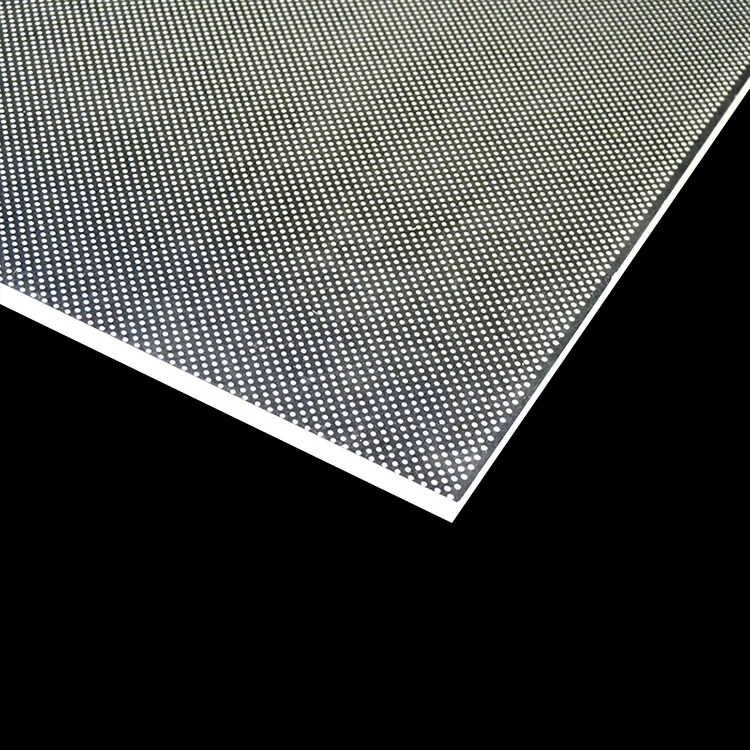

LGP acrylic sheet (Light Guide Plate (LGP) Acrylic Sheet ) is a clear acrylic panel that is manufactured using only virgin PMMA sheet material. It ensures that the light from the source is uniformly distributed throughout the top surface of the acrylic panel. This helps to maintain the consistency of the backlighting and reduces the thickness of the panel. It can also redirect the light from the point light sources to the plate light sources, such as LED lights or decoration lamps. LGP acrylic sheet is an optical-grade panel that has different-sized and dense light guide dots on the surface, which help to spread the light at all angles when an edge light source is applied. This technology is widely used in LCD TV displays.

It is a transparent acrylic panel made from pure PMMA virgin sheets. It distributes the light coming from the light source evenly over the whole upper face to the acrylic panel. It is a key component to maximize the uniformity of light, to make the backlight slim, and to reorient the lines or dot light sources such as decoration lamps or LED to the plate light source.

These sheets are most suitable because of the flat surface with zero thickness variation. This helps in achieving the best results possible.

Specifications

| Product Name | LGP Acrylic Sheet |

| From | China LGP Acrylic Sheet factory - Xishun |

| Origin | Foshan, China |

| Material | PMMA Acrylic |

| Color | Clear/transparent |

| Types | Acrylic sheets |

| Size | 1220*2440mm or 1220*1830mm or customized sizes. |

| Thickness | Commonly 1~30mm |

| Processing Services | Moulding, Cutting, Polishing, Drilling, UV Printing, etc. |

| Supply Ability | Around 1200 tons/month. |

| Advantages | 1. excellent transparency, transmittance 92%. |

| 2. lightweight. | |

| 3. good mechanical processability, easy to process. | |

| 4. non-toxic. | |

| 5. excellent chemical resistance. | |

| 6. real images and modern designs with elegant interior looks can be displayed and seen through computer graphics. | |

| 7. offers LED products slim frame. | |

| 8. the best method for advertisement. | |

| 9. can help to reduce 70% on electricity consumption and offers 10X longer lifespan than traditional LED, Neon and Halogen products. |

Product Features

Excellent transparency, transmittance 92%.

Real images and modern designs with elegant interior looks can be displayed and seen through computer graphics.

Offers LED products with a slim frame.

The best advertisement method.

LED can help to reduce 70% on electricity consumption and offers a 10X longer lifespan than traditional LED, Neon, and Halogen products.

Application of LGP Acrylic Sheets

- Lighting box

- Advertising sign

- LED cover

- Signage

- Lighting cover

How to join acrylic sheets?

Acrylic sheets can be joined together at home in two ways. Before you begin make sure your acrylic sheets have clean, smooth, flat surfaces where they are to join.

Capillary Cementing: This method bonds two pieces of acrylic that fit perfectly together in 48 hours. If your acrylic pieces do not fit perfectly together, use the Viscous Cementing method below. Clamp your pieces of acrylic in place so their joint is horizontal and apply cement along it with a needle nozzle applicator. The horizontal position is important to stop the adhesive from running out. For L shapes, apply the cement along the length of the joint from the inside. Allow 24 hours for bond strength to develop.

Viscous Cementing: This method bonds parts that don't fit properly together as well as joints that are hard to reach. Apply the cement-like glue to one edge of the acrylic then gently press this to the other piece of acrylic, holding the pieces together for about a minute. To allow the bond to develop leave it for 24 hours in a clamp.

If you are looking for a factory of LGP Acrylic Sheet, welcome to contact us, Xishun is your best choice for acrylic sheets. You can enjoy excellent acrylic sheets and service, contact us now!

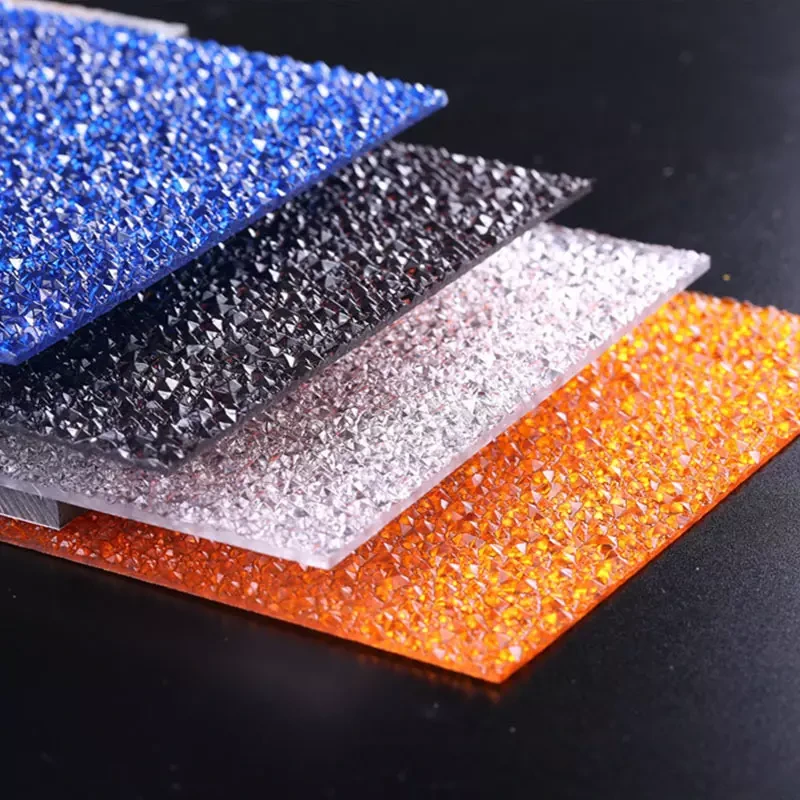

Q: How is LGP acrylic sheet different from regular acrylic?

A: LGP acrylic sheet is an optical-grade panel that has different-sized and dense light guide dots on the surface, unlike regular acrylic.

Q: What are the benefits of using LGP acrylic sheet?

A: LGP acrylic sheet ensures that light is evenly distributed throughout the entire surface of the panel, which can enhance the consistency of backlighting and reduce panel thickness.

Q: What types of applications is LGP acrylic sheet commonly used for?

A: As the following mentions, they are commonly used in signage and display applications such as light boxes, backlit signs, LCD TV displays, and more.

Q: How is LGP acrylic sheet installed?

A: LGP acrylic sheet can be installed by placing a light source at the edge of the panel, causing the light to spread to all angles through the light guide dots and distributing the light evenly on the light guide plate.

Q: Is LGP acrylic sheet more expensive than regular acrylic?

A: Yes, LGP acrylic sheet is generally more expensive than regular acrylic due to its optical-grade properties and light guide technology.

Q: Where can I invest in LGP acrylic sheets at great prices?

A: Xishun is your ideal choice, we are a manufacturer and factory, you can get LGP acrylic sheets at great prices.