Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

acrylic sheet manufacturing

Acrylic sheets are versatile and widely used in various industries due to their transparency, durability, and ease of fabrication. As a manufacturer, we specialize in acrylic sheet manufacturing, ensuring high-quality products that meet specific product requirements while offering competitive pricing. In this article, we will delve into the world of acrylic sheet manufacturing, discussing the process, features, and benefits of these versatile sheets.

Understanding Acrylic Sheet Manufacturing:

Acrylic sheet manufacturing involves a series of processes to transform raw acrylic material into flat sheets of varying thicknesses. The two main methods used in manufacturing are casting and extrusion. Casting involves pouring liquid acrylic into a mold and allowing it to cure, while extrusion involves pushing the acrylic material through a die to form continuous sheets.

Raw Material Selection:

The manufacturing process begins with the selection of high-quality raw materials. Acrylic polymers, also known as polymethyl methacrylate (PMMA), are chosen for their excellent optical clarity, impact resistance, and weatherability. The raw materials are carefully sourced to ensure consistency and quality in the final product.

Casting Process:

In the casting process, liquid acrylic is poured into a mold and allowed to cure. The mold can be of various sizes and shapes, depending on the desired dimensions of the acrylic sheets. The curing process may involve the use of heat or chemical catalysts to accelerate the polymerization and solidification of the acrylic material.

Extrusion Process:

Extrusion is another common method used in acrylic sheet manufacturing. In this process, the acrylic material is melted and forced through a die, which determines the thickness and width of the resulting sheets. The extruded sheets are then cooled and cut into the desired lengths.

Quality Control:

Throughout the manufacturing process, strict quality control measures are implemented to ensure that the acrylic sheets meet the required specifications. This includes monitoring the temperature, curing time, and thickness of the sheets. Additionally, visual inspections are conducted to check for any defects or imperfections.

Features and Benefits of Acrylic Sheets:

Acrylic sheets offer numerous features and benefits that make them a preferred choice in various industries. They have excellent optical clarity, allowing for high light transmission and clear visibility. Acrylic sheets are also lightweight, making them easy to handle and install. They have superior impact resistance compared to glass, reducing the risk of breakage and ensuring safety. Additionally, acrylic sheets are weather-resistant, UV-stable, and can withstand harsh environmental conditions without yellowing or degrading.

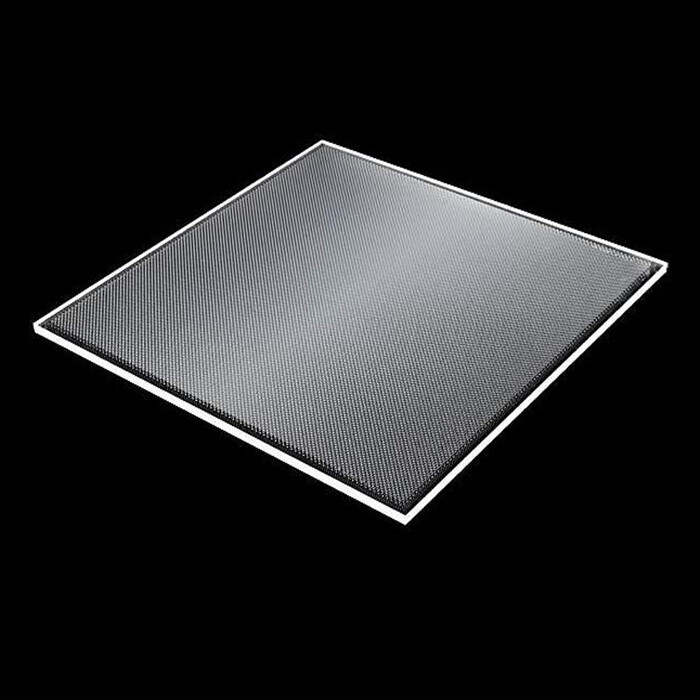

Lgp Acrylic Sheet

A transparent acrylic panel manufactured from virgin sheets of pure PMMA is called a Light Guide Plate (LGP) acrylic sheet. It uniformly disperses the light from the light source across the acrylic panel's entire top face. It is essential for maximizing light uniformity, creating a compact backlight, and reorienting lines or dot light sources, like LEDs or accent lamps, to the plate light source.