Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

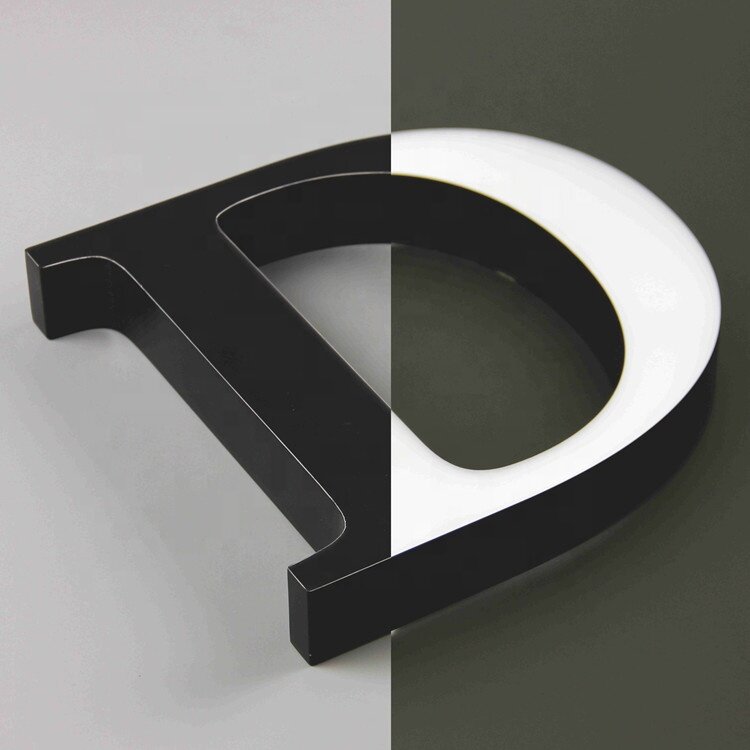

Day Night Acrylic Sheet

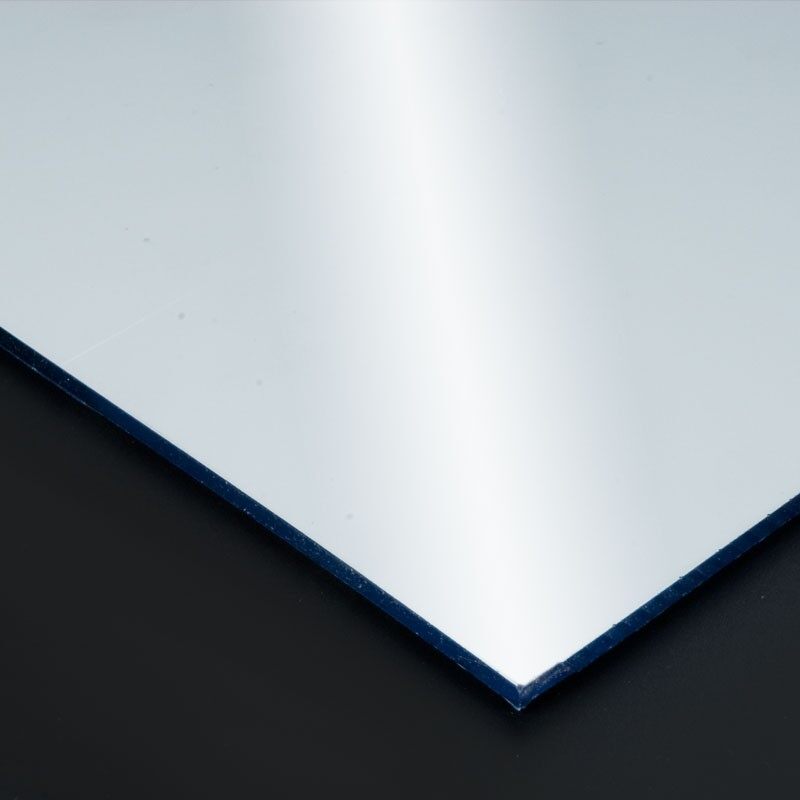

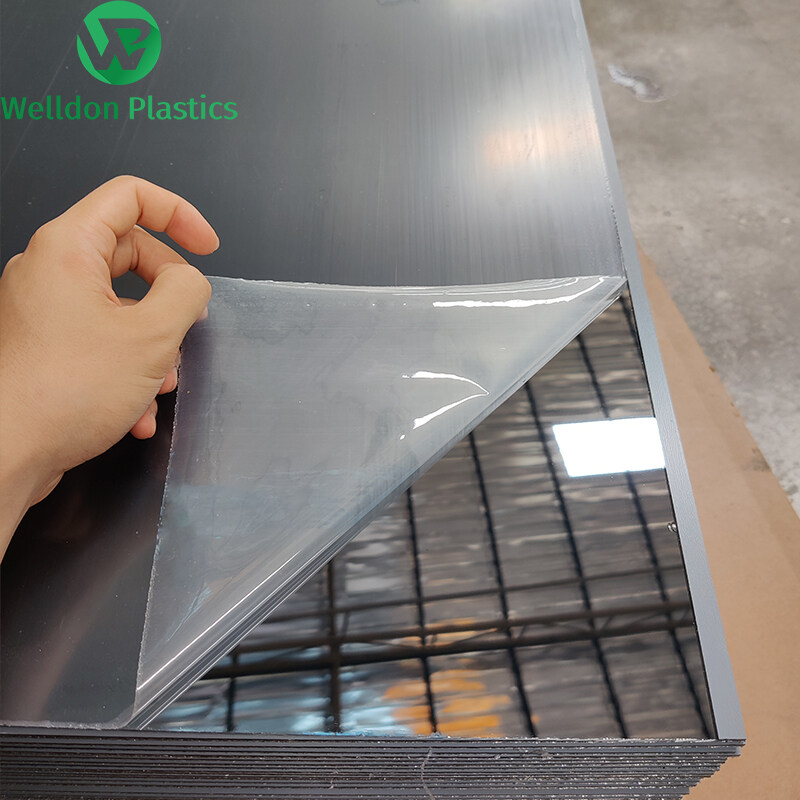

When lighted at night, our Day Night Acrylic Sheet appears white during the night but is black during the day. Excellent light transmittance, durability and impact resistance are all qualities of this Black/White Acrylic. Day Night Acrylic Sheet is the perfect plastics material for a wide range of industrial and commercial uses. Acrylic sheeting is available from us at great internet prices.

Our Day Night Acrylic Sheet looks black during the day but turns white when lit at night. This Black/White Acrylic features excellent light transmittance, durability and impact resistance. Day Night Acrylic Sheet is an ideal plastics solution for a wide variety of business and commercial applications. We offer acrylic sheeting at fantastic online prices.

Product Features

Weather Resistance

Excellent Impact Resistance

Maintains quality after years of use

Eliminates the need for perforated vinyl

Black during the day & white or LED color at night

Cut, bend, glue & form

Product Applications

Building Signs

Cabinet Light Boxes

Channel Letters

Wayfinding Signs

How to finish off acrylic sheet edges?

If you want to smooth and square off acrylic sheet edges for a better finish, or to prepare them ready to join to another acrylic sheet, you will need to scrape first and then file. Scrape along the cut edge with a clean, hard, sharp, square-edge tool (clean back of a knife blade). Next, fill the scraped edges with a 300mm clear, smooth-cut file working in one direction only. It is important to file on an angle and keep the teeth flat on the acrylic surface (to stop any unwanted grooves from cutting into your acrylic). If you are filing a small piece of acrylic, it might be easier to clamp your file and rub your acrylic across it.

How to polish acrylic sheets?

Acrylic's glass-like transparency can be polished to a high shine. And the job is a fairly easy one to do with a little know-how. Choose to do this with either a sand-papering technique or by using a paste suitable for acrylic.

How to bend and form acrylic?

When acrylic is soft, it can be formed into almost any shape. This shape will be retained if it is held until the acrylic is cool. Specialized heating and forming equipment is usually needed, but simple projects with straight line bends can be done by using a strip heater. Lie the acrylic on the heater with the bend line above the heating element. When the acrylic sags, bend it away from the heated side. For 4.5mm and thicker acrylic sheets, heat both sides of the acrylic. Please note acrylic must be heated in a ventilated space – never a kitchen oven.