Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

heat forming acrylic sheet

Heat forming acrylic sheets is a specialized process that allows for the shaping and molding of acrylic material using heat. This technique offers a wide range of design possibilities and applications. In this article, we will delve into the world of heat forming acrylic sheets, discussing the process, applications, and the advantages they offer.

Understanding Heat Forming Acrylic Sheets:

Heat forming acrylic sheets involves heating the material to a specific temperature, making it pliable and allowing it to be shaped into desired forms. The heated acrylic sheet can be bent, curved, or molded into various shapes and sizes. This process enables the creation of unique and customized designs.

Versatile Applications:

Heat forming acrylic sheets find a wide range of applications across different industries. In the retail sector, they are used for product displays, signage, and point-of-sale materials, creating eye-catching and visually appealing presentations. In the automotive industry, they are utilized for interior components, such as dashboards and instrument panels. Additionally, they are used in the medical field for equipment enclosures and protective barriers.

Customization Options:

One of the key advantages of heat forming acrylic sheets is the ability to customize them according to specific design requirements. The sheets can be shaped into various forms, including curves, angles, and complex geometries. This allows for the creation of unique and tailored solutions for different projects.

Enhanced Aesthetic Appeal:

Heat forming acrylic sheets offer enhanced aesthetic appeal compared to flat sheets. The ability to create curved or molded shapes adds depth and visual interest to the final product. This makes heat-formed acrylic sheets ideal for applications where a sleek and modern appearance is desired.

Durability and Impact Resistance:

Heat-formed acrylic sheets retain the durability and impact resistance of standard acrylic sheets. They are resistant to breakage, scratches, and fading, ensuring their longevity and performance over time. This makes them suitable for both indoor and outdoor applications, as they can withstand various environmental conditions.

Ease of Fabrication:

Heat-formed acrylic sheets are easy to fabricate and work with. They can be further cut, drilled, and bonded to other materials, allowing for seamless integration into existing structures or the creation of complex assemblies. This versatility makes them a preferred choice for professionals and DIY enthusiasts alike.

Cost-Effective Solution:

Heat forming acrylic sheets offer a cost-effective solution for businesses and individuals. The ability to shape the material reduces the need for additional manufacturing processes or the use of more expensive materials. Additionally, bulk production options and competitive pricing make heat-formed acrylic sheets an affordable choice for large-scale projects.

Conclusion:

Heat forming acrylic sheets provide a versatile and customizable solution for various projects. With their ability to be shaped into unique forms, durability, and cost-effectiveness, these sheets offer a practical and visually appealing option for businesses and individuals. Experience the benefits of heat-formed acrylic sheets in your next project, whether

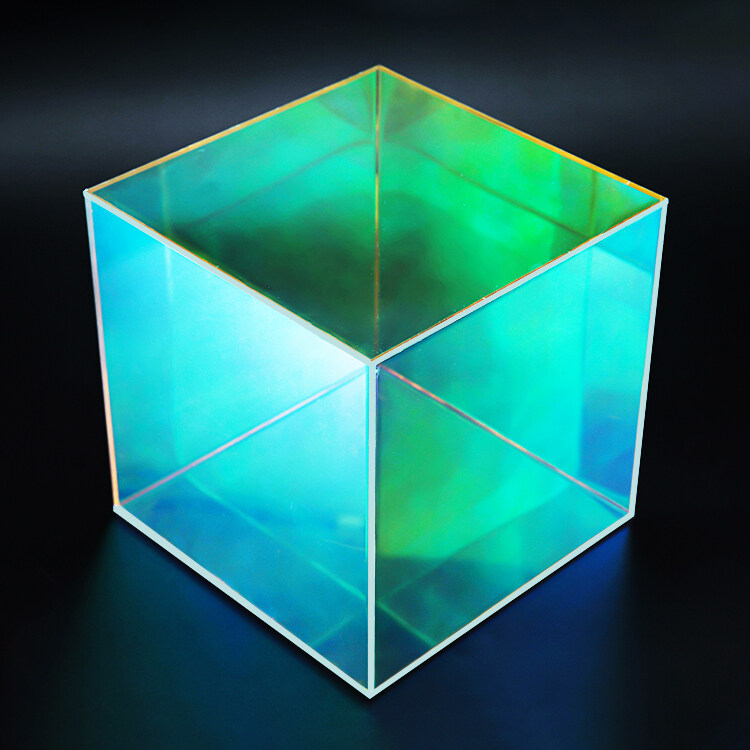

Bonding & Forming Acrylic Sheet

Our bonding & forming acrylic sheets are the epitome of versatility and functionality in the realm of acrylic solutions. These sheets are crafted to meet the rigorous demands of both bonding and forming applications, providing a reliable and high-quality option for professionals across various industries.